|

|

|

Getinge Ventilator terminal sterilizers (GEVs)

|

| |

| The GEV offers unique flexibility and can be used in a wide variety of applications and provides significant benefits over other sterilization techniques, for example: |

| |

|

Liquid pharmaceutical products. For example packaged in vials or syringes. These products may be sensitive to pressure changes (esp. syringes) which may displace the rubber stopper or other closure system. The GEV accurately balances the chamber pressure with the internal product pressure to minimize pressure differential and therefore eliminate closure disruption. In addition, the GEV uses it's drying and cooling capability to ensure residual moisture is removed an the product is available immediately after sterilization for downstream processing (inspection and labelling). |

|

|

|

Components, such as rubber stoppers, are traditionally sterilized in a steam sterilizer. However, this is a long process because rubber is a poor conductor of heat and it is difficult to remove condensate created during heating. The GEV uses its powerful fan to preheat the stoppers, reducing condensation, resulting in shorter cycles. |

|

Blister packed products are difficult to sterilize by any other means than the GEV, making this machine indispensable to clients producing blister-packed vials, syringes, contact lenses, etc. |

|

Medical device producers often select EO or radiation sterilization. However, the GEV has been successfully used in many MD applications - for example - dialysis filters - and offers significant cost savings compared with EO or radiation. |

|

In the laboratory (or vaccine production), the GEV may be used for rapid sterilization of culture media - especially when large volumes and/or heat labile media are involved. |

| |

|

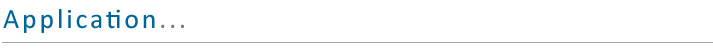

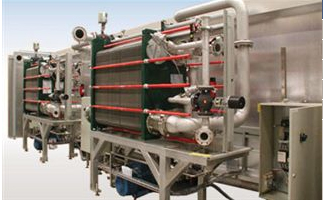

| Getinge Circulating Water Terminal sterilizers (GECs) |

| |

| The GEC sterilizer is dedicated to a single purpose: rapid sterilization of fluids in sealed containers. Most typically these are parenteral products such as: |

|

|

| |

|

Small volume parenterals (SVP) such as vials, ampoules (up to 100ml) |

|

Large (LVP) volume parenterals (LVP) such as water, saline, dextrose in sealed glass or plastic containers, including bags. |

|

Other injectables products such as dialysis solutions or Total Parenteral Nutrition (TPN) products, in sealed bags. |

| |

|

| These products – in bags or bottles – are usually processed in bulk with large batch quantities and require rapid, efficient processing. |

| |

The GEC, with adequate utilities, can provide very rapid heating and cooling, with cycles times of around 1 hour. |

|

|